The ISAC β-NMR HomePage

| Introduction to β-NMR |

Publications |

Students Projects |

Contacts |

| Technical Information |

Data Acquistion |

Approved Experiments |

Internal Page |

| Related Links |

BNMR Wiki |

Data Analysis |

Photo Album |

|

|

Changing Sample in the High Field Spectrometer

The entire procedure should take about 1 hour

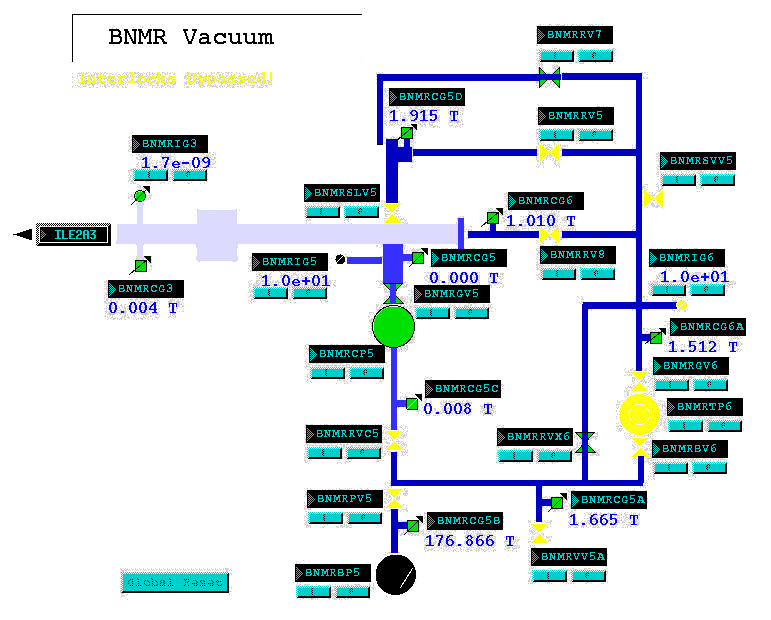

EPICS Vacuum page in the control room

A sample is in the cryostat and you want to get it out

-

If the load lock is under vacuum, vent it through SVV5 (see figure above) note there is a manual valve in line with this automatic valve.

-

Remove the blankoff on the top of the lock by undoing the three bolts with the allan key located on the side of the lock.

-

Keeping the rubber o-ring in place, mount the clean end of the manipulator into the vacuum lock and seal it using the three screws and the allan key. Do not get the manipulator's clean end dirty by touching it with your bare hand for example.

- Rough out the lock:

Make sure the vent valve SVV5 is closed

Turn on the roughing pump if it is off. (the round black circle BNMRBP5 above should be green)

Note the Fuji dry roughing pumps are often switched off due to their short lifetimes

If the roughing pump is working the convectron gauge BNMRCG5 should go down to some low value like 50 mT - that's T for Torr

Open the valves to the lock: PV5, RVX6 and RV5

You can watch it rough down on the convectron gauges CG6A and CG5D

- Rough out the backside of the sliding seal:

Close RV5

Note typically the lock pressure comes up when you isolate it due to outgassing this can be seen on CG5D

Open RV7

Watch it pump out on convectron CG6A

-

Spin Up the Turbo Pump BNMRTP6 - the yellow circle above

When it is safe, open the inlet side of TP6 using GV6

-

Pump out the lock and the backside of the sliding seal:

Pump the lock for ~ 15mins

The gauge CG5D will quickly bottom out, but

After a while you can turn on the ion gauge IG6 at the turbo and watch it come down to a few microTorr

-

Prepare to open the gate valve:

Close RV5, isolating the lock

Then QUICKLY open RV7 to pump on the "differential space" at the back of the sliding seal

If you are too slow the TP will trip off and you have to turn it back on.

Note when the manipulator is going into the UHV space, you must pump continuously on the differential space with the turbo

Let it pump for a minute or two

-

Open the gate valve (SLV5) now the lock is open and the UHV is spoiled (not badly if you have followed the above)

-

Go to the platform push the manipulator down, opening the hatch if you haven't already

-

Using the motor and the side-to-side play of the bellows on the lock position the manipulator directly over the threaded hole in the sample holder

-

Unscrew the sample: note this is a reverse thread, so you turn as if you were taking it out (pressenig gently to engage the threads). This is Counterclockwise!

-

Once the reverse thread is fully engaged, the outer normal threads will begin to pull out. Continue turning the same way until the holder is free

-

Retract the manipulator (with holder attached) into the lock all the way

Once this is done, close the gate valve from the control room SLV5

-

Vent the lock

- Remove sample and manipulator (without touching the clean end)

Turn off the roughing pump if you are going to be a while.

The cryostat is empty and you want to install a sample

-

If the load lock is under vacuum, vent it through SVV5 (see figure above) note there is a manual valve in line with this automatic valve.

-

Remove the blankoff on the top of the lock by undoing the three bolts with the allan key located on the side of the lock.

-

Keeping the rubber o-ring in place, mount the clean end of the manipulator into the vacuum lock and seal it using the three screws and the allan key. Do not get the manipulator's clean end dirty by touching it with your bare hand for example.

- Rough out the lock:

Make sure the vent valve SVV5 is closed

Turn on the roughing pump if it is off. (the round black circle BNMRBP5 above should be green)

Note the Fuji dry roughing pumps are often switched off due to their short lifetimes

If the roughing pump is working the convectron gauge BNMRCG5 should go down to some low value like 50 mT - that's T for Torr

Open the valves to the lock: PV5, RVX6 and RV5

You can watch it rough down on the convectron gauges CG6A and CG5D

- Rough out the backside of the sliding seal:

Close RV5

Note typically the lock pressure comes up when you isolate it due to outgassing this can be seen on CG5D

Open RV7

Watch it pump out on convectron CG6A

-

Spin Up the Turbo Pump BNMRTP6 - the yellow circle above

When it is safe, open the inlet side of TP6 using GV6

-

Pump out the lock and the backside of the sliding seal:

Pump the lock for ~ 15mins

The gauge CG5D will quickly bottom out, but

After a while you can turn on the ion gauge IG6 at the turbo and watch it come down to a few microTorr

-

Prepare to open the gate valve:

Close RV5, isolating the lock

Then QUICKLY open RV7 to pump on the "differential space" at the back of the sliding seal

If you are too slow the TP will trip off and you have to turn it back on.

Note when the manipulator is going into the UHV space, you must pump continuously on the differential space with the turbo

Let it pump for a minute or two

-

Open the gate valve (SLV5) now the lock is open and the UHV is spoiled (not badly if you have followed the above)

-

Go to the platform push the manipulator down, opening the hatch if you haven't already

-

Using the motor and the side-to-side play of the bellows on the lock position the manipulator directly over the threaded hole in the sample holder

-

Screw the sample in: note this is a normal thread, so you turn as if you were taking it in (pressenig gently to engage the threads). This is Clockwise!

-

Once the thread is fully engaged, the inner reverse threads will begin to pull out. Continue turning the same way until the manipulator is free

-

Retract the manipulator (without the holder) into the lock all the way

Once this is done, close the gate valve from the control room SLV5

- Turn off the turbo pump, and then turn off the roughing pump.

Page last modified: 07/23/09 02:45 by Andrew MacFarlane.